Deck tunnel ovens

The ovens are intended for baking of all common types of bakery products.

These double-deck ovens are supplied in standard widths (0,6 ÷ 4m). They can be furnished with the accessories, whose overview can be found in oven accessories.

Options of oven modifications

Double-deck oven can be configured in 2 variants so-called „parallel flow“ and „counter flow“.

In variant „parallel flow“ it is possible to bake either only on one deck or on both decks together. For each deck you can choose different temperature and different time for baking and it is also possible to bake the different product on each deck. Direction is the same for both decks – parallel flow.

In variant „counter flow“ it is possible to bake on both decks only one product at the same time, the baking times are the same for the both decks. The product is set on upper deck and it is automatic set to lower deck and it returns to the beginning of the oven. Baking direction is opposite – counter flow.

Double-deck baking ovens can be cyclothermic, with using of diverse types of gas and liquid fuels, and also with electrical heating.

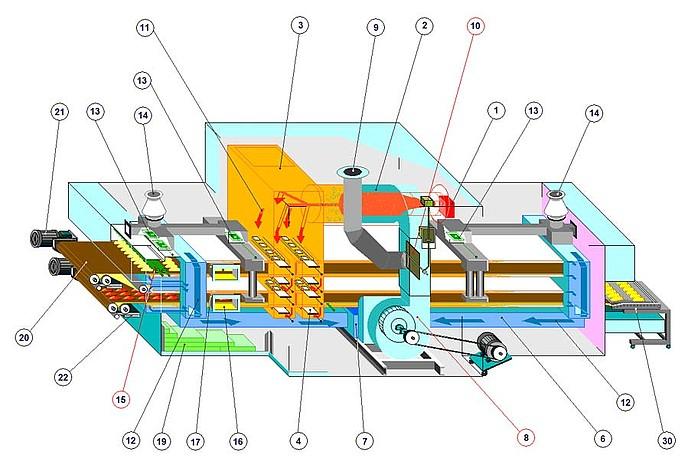

Example of axonometric profile of a double-deck cyclothermic PPP band oven with a wire mesh band. It is a construction of “counter-flow“ with a reloading conveyor between decks:

| 1: | burner | 13: | regulation damper of excess vapours exhaust from the baking chamber |

| 2: | burner chamber | 14: | vapours exhaust |

| 3: | combustion chamber | 15: | dual stainless steel steam pipes with 100% condensate separation |

| 4: | temperature control in the upper and lower radiators | 16: | inspection window |

| 5: | distribution ducts of hot combustion gases | ||

| 6: | return ducts of cold combustion gases | 17: | baking chamber lighting |

| 7: | colleting chamber of cooled combustion gases | 19: | thermal insulation |

| 8: | cyclothermic fan of the heating system with speed control | 20: | wire mesh band conveyor |

| 9: | exhaust chimney for combustion gases from the heating system | 21: | band drive with speed control |

| 10: | safety ventilation flap | 22: | mechanical band tensioning |

| 11: | hot combustion fumes | 30: | roller conveyor for bread reloading |

| 12: | cooled combustion fumes |

-

Band types

-

Production lines